Program Overview

This program is designed to provide the participants with a fundamental understanding of the key principles and methodology of Lean Manufacturing, based on the different aspects of the Toyota Production System, or TPS. It is suitable for staff of all levels who are new to Lean Manufacturing, or looking for a refresher course in the subject area.

By examining the end-to-end process and removing non-value added wastes and activities, the concept and techniques of Lean Manufacturing can therefore bring about significant benefits such as improved profitability, increased customer satisfaction and improved company-wide teamwork, to an organisation.

Learning Outcome

The philosophy and methodology of Lean Manufacturing

Important Lean Manufacturing methods and techniques such as 5S, value stream mapping, mistake-proofing, total productive maintenance, batch size optimisation, layout optimisation, and others

Recognize the difference between conventional “push” and the lean “pull” systems

Comprehend the lean principles and their advantages

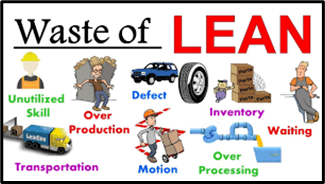

Determine common types of waste and how those wastes impact an organization’s revenues

Determine how lean considers the removal/reduction of operating costs, cycle time, and non-value added actions

Use employees’ time and their brainpower more efficiently in a team environment

Recognize customer value and waste

Identify the wastes and how to cut them down

Recognize fields for improvement and solutions

Comprehend how a team-based technique to change can accomplish sustainable results

Key steps for a successful implementation of Lean Manufacturing

Common pitfalls and challenges in implementing Lean Manufacturing

Program Outline

Module 1: Introduction to LEAN MANUFACTURING

Module 2 : Kaizen Fundamentals

Module 3: Five Principles of Lean

Module 4: Waste Identification

Module 5: Lean Practices/ Tools

Module 6: Building Lean Culture

Course Summary – Developing your Action Plan

Who Should Attend:

This program is designed for Technician, Supervisors, Engineers, Executives and Managers who are involve in either manufacturing or service sector who want to improve their process efficiencies by implementing LEAN.

Methodology

This stimulating program will maximize understanding and learning through Interactive Lectures, Course notes, Videos, Learning Assessment after each Module